ONLINE CONSULTATION

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

PRODUCT DESCRIPTION

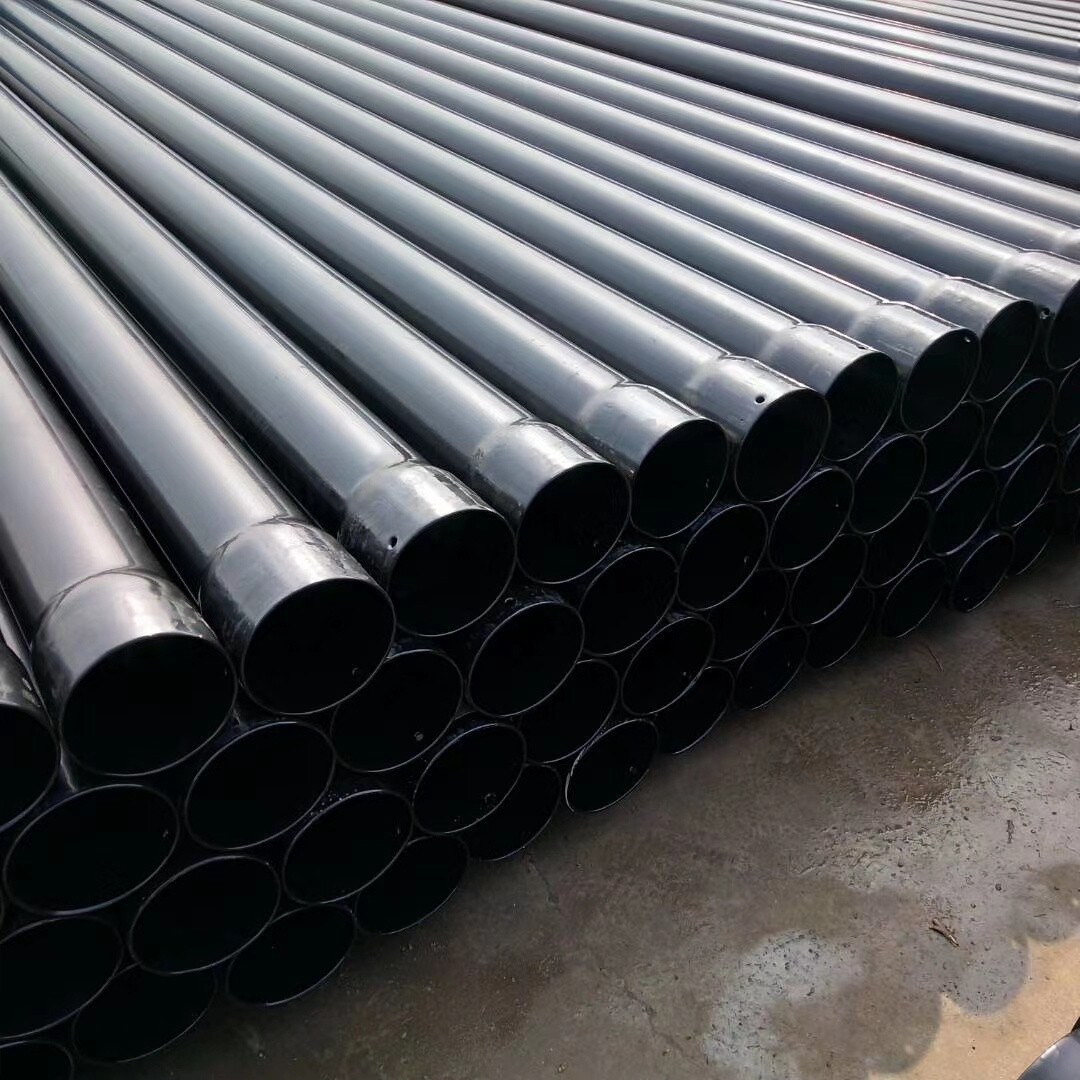

External Epoxy Coal Tar Anti-corrosion Steel Pipe Introduction

External epoxy coal tar anti-corrosion complies with SY/T 0447-96 standard.

Epoxy coal pitch anti-corrosion coating is composed of two main components: epoxy and coal pitch. It is a two-component coating of A (epoxy) and B (curing agent). It has excellent adhesion, toughness, moisture resistance, water resistance, and water resistance. The chemical medium has the ability to prevent various ions from penetrating the paint film, and has the characteristics of expanding and contracting at the same time as the object being painted. The paint film never peels off or cracks, with a thickness of 0.2-0.5mm.

This product is a high-performance anti-corrosion coating. The coating is smooth, dense, hard, has strong adhesion, is resistant to salt and alkali, sea water, soil microbial corrosion, and has excellent resistance to plant rhizome penetration. The combined use of paint and fiberglass cloth can enhance the mechanical properties of the anti-corrosion layer. The conventional method is to use epoxy coal pitch and glass silk cloth for anti-corrosion: one cloth and two oils, three oils and two cloths, three cloths and five oils, six oils and four cloths, etc. are mainly used for buried or underwater steel oil, gas, water supply and anti-corrosion of the outer wall of heating pipes. It is also suitable for the anti-corrosion of various steel structures, docks, ships, sluices, gas storage tanks, refinery and chemical plant equipment, and the waterproofing and anti-leakage of concrete structures such as concrete pipes, sewage pools, roof waterproofing layers, toilets, and basements.

Outer Wall Epoxy Coal Tar Anti-corrosion Steel Pipe Structure

Epoxy coal tar anti-corrosion structure: The anti-corrosion coating made of epoxy resin + coal tar pitch + filler is applied on the steel pipe surface with glass cloth as a reinforcement coating to form an anti-corrosion layer, which is commonly used for pipeline outer wall anti-corrosion. The thickness is generally 0.5~1.0mm.

Service life: about 40 to 50 years

IPN8710 non-toxic drinking water anti-corrosion steel pipe product introduction

IPN8710 non-toxic drinking water anti-corrosion steel pipe implements SY/T0457-2010 standard.

IPN8710 non-toxic drinking water anti-corrosion coating is a non-toxic high-quality drinking water coating with good anti-corrosion performance. It is anti-rust, no irritating taste, non-toxic after curing. The coating structure is dense, waterproof and permeable, strong adhesion, and the coating is tough and plump.

IPN8710 primer: It is composed of polyurethane polyethylene, modified epoxy resin, non-toxic anti-rust pigment filler, additives, etc., solidified at room temperature to form an interpenetrating network, dense coating structure, acid, alkali, salt resistance, excellent anti-rust performance, strong adhesion.

IPN8710 topcoat: It is composed of epoxy, rubber resin modified, non-toxic anti-rust pigment filler, additives, etc. Excellent chemical resistance, non-toxic, anti-microbial erosion.

Coating method: brushing or high-pressure airless spraying

Application: IPN8710 primer is used for anti-corrosion of the inner wall of drinking water pipelines

COMPANY PROFILE

Lianhang (Hebei) International Trade Co., Ltd. is a company specializing in the production of steel pipes. The company is located north of Beijing Tianjin and east of Tianjin Port, with convenient transportation and an area of 286 acres.

The company's main products include seamless steel pipes, straight seam steel pipes, spiral steel pipes, anti-corrosion and insulation steel pipes, with various models and complete standards, and high-quality products at competitive prices.

ONLINE CONSULTATION

PRODUCTS RECOMMENDED

Get real-time quotes

Interested? Leave your contact details.